Crystal Bonding-Composite Technology ntawm Laser Crystals

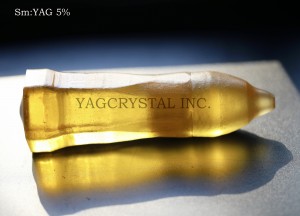

Product Description

Qhov tseem ceeb ntawm daim ntawv thov kev sib txuas tshuab ntawm laser muaju nyob rau hauv: 1.Miniaturization thiab kev koom ua ke ntawm laser li / systems, xws li Nd:YAG/Cr:YAG bonding rau zus tau tej cov passive Q-hloov microchip lasers;2. Kev txhim kho thermal stability ntawm laser rods Performance, xws li YAG / Nd: YAG / YAG (uas yog, bonded nrog ntshiab YAG los tsim lub thiaj li hu ua "kawg cap" ntawm ob qho tag nrho ntawm lub laser pas nrig) tuaj yeem txo qhov siab Qhov kub nce ntawm lub ntsej muag kawg ntawm Nd: YAG pas nrig thaum nws ua haujlwm, feem ntau yog siv rau cov khoom siv hluav taws xob siv hluav taws xob thiab cov khoom siv hluav taws xob hauv lub xeev lasers uas yuav tsum tau ua haujlwm siab.

Peb lub tuam txhab tam sim no lub ntsiab YAG series bonded siv lead ua khoom muaj xws li: Nd: YAG thiab Cr4 +: YAG bonded rods, Nd: YAG bonded nrog ntshiab YAG ntawm ob qho tag nrho, Yb: YAG thiab Cr4 +: YAG bonded rods, thiab lwm yam.;diameters los ntawm Φ3 ~ 15mm, ntev (thickness) los ntawm 0.5 ~ 120mm, kuj tuaj yeem ua tiav rau hauv square strips lossis square sheets.

Bonded siv lead ua yog ib yam khoom uas sib txuas ib lub laser siv lead ua nrog ib los yog ob lub ntshiab uas tsis yog-doped homogeneous substrate cov ntaub ntawv los ntawm kev sib txuas tshuab kom ua tau ib tug ruaj khov ua ke.Cov kev sim qhia tau hais tias kev sib koom ua ke muaj peev xwm tuaj yeem txo qhov kub ntawm laser muaju thiab txo qhov cuam tshuam ntawm thermal lens tshwm sim los ntawm qhov kawg ntawm lub ntsej muag deformation.

Nta

● Txo thermal lensing tshwm sim los ntawm qhov kawg ntawm lub ntsej muag deformation

● Txhim kho lub teeb-rau-lub teeb hloov dua siab tshiab

● Muaj zog tiv thaiv photodamage pib

● Txhim kho laser tso zis beam zoo

● Txo qhov loj me

| Flatness | <λ/10@632.8nm |

| Nto zoo | 10/5 |

| Parallelism | <10 arc vib nas this |

| Verticality | <5 feeb |

| Chamfer | 0.1 hli @ 45 ° |

| Txheej txheej | AR lossis HR txheej |

| Optical zoo | Interference fringes: ≤ 0.125 / nti Interference fringes: ≤ 0.125 / nti |